Sublimation Tumblers has evolved from a niche hobby to a sought-after craft, allowing individuals to add a personal touch to their drinkware. Often perceived as a complex process requiring specialized equipment, sublimation can actually be accomplished effectively using a regular oven. In this comprehensive guide, we’ll walk you through the intricate process of sublimating tumblers in a conventional oven, covering everything from the essential equipment to the optimal temperature and time recommendations.

Materials Required

To embark on your sublimation journey, gather the following materials:

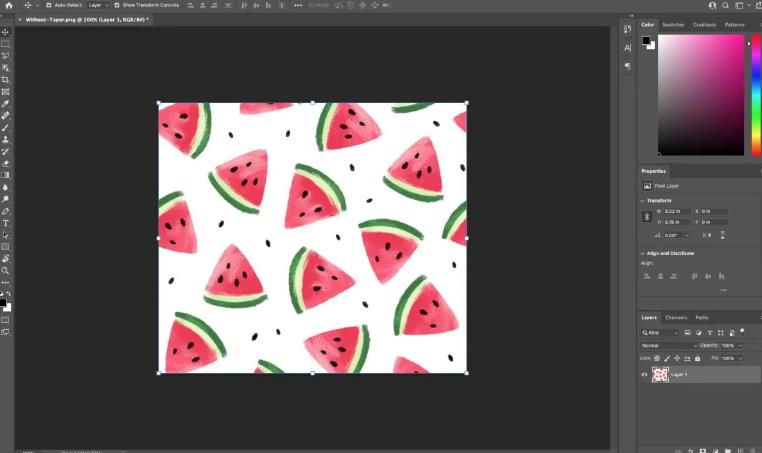

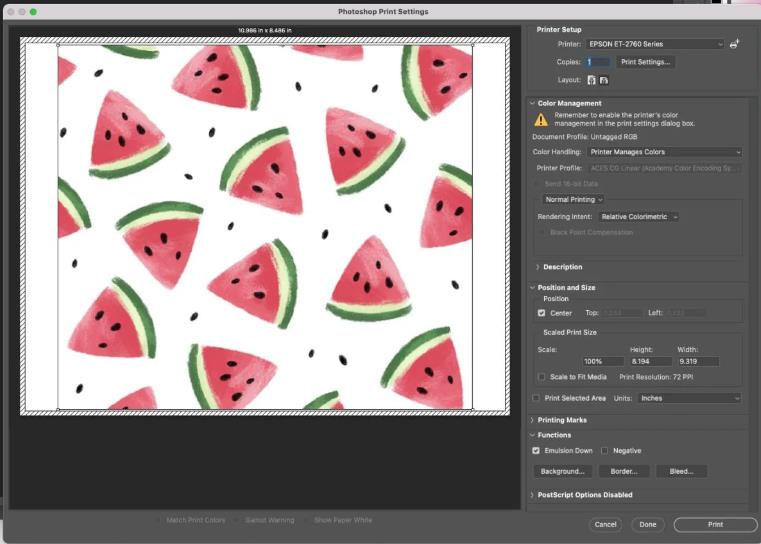

Step 1: Preparing Your Design

Begin by creating or selecting the design you want to sublimate onto the tumbler. Use graphic design software to ensure the dimensions match the tumbler’s surface. Mirror the design horizontally since sublimation prints in reverse.

Step 2: Printing the Design

Print the mirrored design onto sublimation paper using a sublimation printer and ink. Ensure your printer settings are optimized for sublimation printing. Allow the ink to dry completely before proceeding.

Step 3: Preparing the Tumbler

Clean the tumbler’s surface thoroughly to remove any dirt, dust, or oils. Even the smallest imperfections can affect the sublimation process. Use a lint-free cloth and isopropyl alcohol for effective cleaning.

Step 4: Applying the Design

Wrap the sublimation paper around the tumbler, positioning the design precisely where you want it. Secure the paper in place using heat-resistant tape. The tape prevents the paper from moving during the sublimation process.

Step 5: Preheating the Oven

Preheat your regular oven to the recommended temperature of around 380°F (193°C). Use an oven thermometer to ensure accuracy. This temperature provides the ideal environment for sublimation ink to transfer onto the tumbler’s coating.

Step 6: Sublimating in the Oven

Place the tumbler with the secured sublimation paper in the preheated oven. Make sure the tumbler is stable and won’t tip over during the process. Close the oven door and set a timer for the recommended duration of 12 to 15 minutes.

Step 7: Monitoring the Process

Keep a close eye on the oven thermometer to maintain a consistent temperature throughout the sublimation process. Fluctuations in temperature can impact the final result. Avoid opening the oven door unnecessarily, as this can lead to heat loss.

Step 8: Completing the Sublimation

Once the timer goes off, carefully remove the tumbler from the oven using heat-resistant gloves. Place it on a heat-resistant surface and allow it to cool for a few minutes.

Step 9: Removing the Sublimation Paper

Gently peel off the heat-resistant tape and sublimation paper to reveal your design. The ink should have transferred onto the tumbler’s coating, creating a vibrant and permanent image.

Step 10: Finalizing the Process

Let the tumbler cool completely before handling or using it. This ensures the sublimation ink fully adheres to the coating, providing a long-lasting and durable design.

2. What kind of oven can you use for sublimation for tumblers?

When it comes to sublimating tumblers in an oven, the choice of oven is critical for achieving consistent and high-quality results. While various types of ovens exist, not all are suitable for the sublimation process. Here’s a detailed overview of the types of ovens you can use and the factors to consider:

sublimation tumbler in convection oven: The Ideal Choice

A convection oven is the recommended option for sublimating tumblers. Convection ovens are equipped with fans that circulate hot air, ensuring even heat distribution. This uniform heat distribution is essential for achieving consistent and vibrant sublimation results across the entire surface of the tumbler.

Essential Tips

Oven Thermometer: Regardless of the type of oven you use, it’s crucial to use an oven thermometer to ensure the oven’s internal temperature matches your settings.

Preheating: Preheat the oven thoroughly to the recommended sublimation temperature before placing the tumbler inside. This helps maintain a consistent environment throughout the process.

Monitor Carefully: Keep a watchful eye on the oven thermometer to prevent temperature fluctuations during the sublimation process.

3. What temperature and time for sublimation tumblers for beginners?

Temperature

Preheat your oven to approximately 380°F (193°C). This temperature forms the cornerstone of successful sublimation.

Time

Place the tumbler inside the oven for a duration of 12 to 15 minutes. This window strikes a balance between allowing the ink to fully sublimate and preventing overexposure.

Factors Affecting Time and Temperature

Tumbler Material and Coating: Different materials and coatings may require slight adjustments in temperature and time. It’s essential to refer to the manufacturer’s guidelines for the specific tumblers you’re using.

Sublimation Ink and Paper: High-quality sublimation ink and paper combinations have recommended temperature and time settings provided by the manufacturer. These guidelines ensure optimal results.

Oven Performance: Each oven behaves slightly differently. Factors such as heat distribution and accuracy of temperature control can affect the sublimation process. Using an oven thermometer to monitor the internal temperature is crucial.

4. The Art of Fine-Tuning: Personalizing Your Approach

Testing and Adjustment

Factors such as your oven’s peculiarities, the sublimation ink’s characteristics, and the paper type can influence the ideal temperature and time. Conducting a series of test runs will enable you to pinpoint the optimal settings for your specific setup.

Achieving Perfection

By meticulously noting the outcomes of each test and gradually adjusting the temperature and time, you can refine your approach to achieve impeccable sublimation results.

Conclusion: A World of Possibilities Awaits

Sublimation tumblers within the confines of a regular oven opens a gateway to creative expression. With the right materials, meticulous attention to temperature and time, and a willingness to experiment, you can master the art of sublimation. As you transform ordinary tumblers into personalized masterpieces, you’ll discover a rewarding journey of self-expression and customer delight. Harness the power of sublimation in your regular oven, and let your imagination flow through vibrant, lasting designs that captivate and inspire.